Margordel Restoration

Year 2

Back to Bones

The blessing of Sunny corner

Sunny Corner has carved out a cherished space in the hearts of all those who partook in this remote and unforgettable journey. We consider ourselves incredibly fortunate not only for the opportunity to lend a helping hand to Pete's Bite during their time of crisis but also for the privilege of spending a full year in this extraordinary location as we painstakingly restored the Margordel.

On the fateful evening of September 7, 2021, tragedy struck when a fire broke out at the Peats Bite Restaurant, situated just around the river's corner from our location. The rapidity with which the restaurant was engulfed by the flames was alarming, but thanks to the efforts of local Rural Fire Service (RFS) teams, the blaze was successfully contained, preventing it from spreading to the neighboring bushland or properties. Fortunately, no one was on-site at the time, except for the brave guard dog, Finn, who emerged unscathed. The property owners were understandably left in a state of shock.

However, from the depths of this terrible tragedy, a new beginning emerged...

We were introduced to the owners of Peats Bite, Tanya, and Geoff, by a Milsons Passage neighbor who recognized their need for on-site assistance and our need for a dock and space to undertake our restoration project. After a meeting, it became clear that we shared a common spirit, and this marked the start of a wonderful relationship.

During this period, we were on the hunt for mahogany to clad the cabin sides, which was part of the restoration plan. Serendipitously, I stumbled upon an advertisement on Gumtree that led me to Taree to meet an old boat builder who possessed a treasure trove of red Brazilian Mahogany planks - 120 linear meters of them, each measuring 5.5 meters in length. This wood, which had been in storage for the past 25 years, was a relic from a long-forgotten boat project. It was a remarkable find and an invaluable addition to our restoration materials.

By October 17, we had the opportunity to move the Margordel to one of Peats Bite's moorings in preparation for our relocation to Sunny Corner. Geoff, in a tireless effort, cleared the burnt debris from their site and arranged for us to stay in a neighboring house.

On November 6, the Margordel was brought alongside at Peats Bite dock. After negotiations with the owner, Tom, of the quaint cottage at number 3 Sunny Corner, we were granted permission to move in. Our transition to Sunny Corner involved a boat loaded with our belongings on November 19. The cottage we moved to had remained uninhabited for several years, and we encountered challenges such as a lack of electricity, non-functional sewage, and water storage tanks that had turned stale and green. We were off the grid, with systems akin to living on a boat. After a few weeks of adapting to candlelight and the installation of new batteries, we were up and running, ready for the next phase of our journey.

Inch by Inch

How do you eat an elephant... I bite at a time...

The marathon of a mission to paint and varnish the entire boat. So many man-hours have gone into this process but the results are amazing

Amidst the crucial timber restoration work, the preparation for painting and varnishing took center stage.

Ensuring that the finished construction was promptly protected was of paramount importance, and the following process was meticulously adhered to:

-

Wash and degrease the surface.

-

Strip old paint from the surface.

-

Sand the surface with 60-80 grit.

-

Wash the surface.

-

Apply Everdure (penetrating epoxy) in 5 coats or prime the surface.

-

Fill any surface imperfections.

-

Sand the filled areas flat.

-

Clean the surface.

-

Prime the surface in 3 coats.

-

Sand the surface with 220 Grit.

-

Apply an undercoat to the surface in 2 coats.

-

Sand the surface with 320 Grit.

-

Topcoat the surface in 2 coats.

This process is undoubtedly repetitive and immensely time-consuming, as known to anyone experienced in marine coatings. The quality and longevity of the finish depend entirely on following the correct procedure. When we say we fully repainted a surface, this is precisely what we mean...

During this period, the following surfaces received a complete repainting:

Inner Hull:

Every inch of the inner hull above the waterline was meticulously stripped using a heat gun and scraper. Greg led the charge on this monumental task, working tirelessly from stem to stern, including every rib and beam on the boat. This task pushed him to his limits, even causing his hands to bleed. Given the expansive area to cover, the initial coats of primer were applied with a brush to ensure comprehensive coverage in all nooks and crannies. Subsequent coats were applied with an airless spray gun to expedite the process. Thankfully, we followed the International Paints process, which allowed us to overcoat the paint without sanding within a specific time frame. This process demanded two months of dedication, but the results were well worth every minute of effort.

Deckhead (ceiling):

The forward cabin's flat deckhead was fortunately straightforward to tackle. However, the rest of the boat featured pinstriped grooves, challenging to prepare for painting. Each groove required careful cleaning by scraping along the edge in two planes, using a heat gun to soften the deteriorated old paint. Greg and Adam took on this formidable task, working tirelessly above their heads for three weeks, every day, all day. Thankfully, we followed the International Paints process, which eliminated the need for sanding between coats.

Sole Boards:

All the removable sole boards were taken out. Those in good condition were treated with Everdure and repainted.

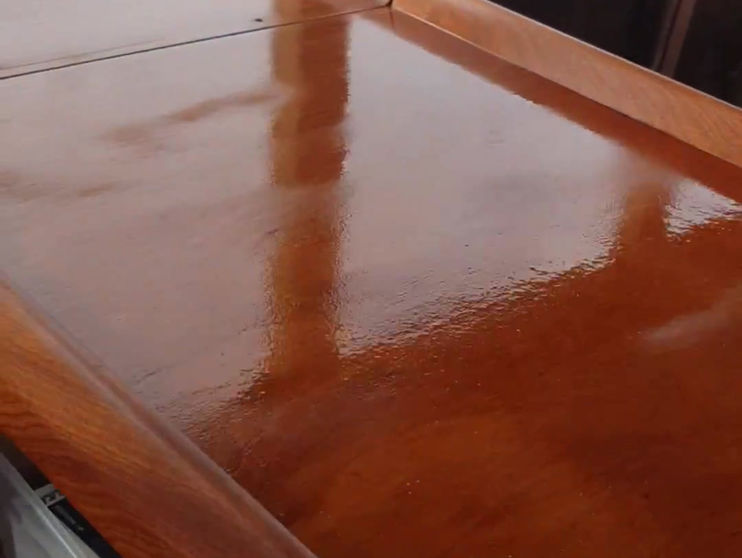

Varnishing:

This was equally crucial for safeguarding the exquisite Mahogany joinery against further deterioration. With much of the incumbent furniture removed, we had improved access to these beautiful surfaces. The saloon was stripped while at Taren Point, and it was time for a final sanding and the commencement of the varnishing process.

The exterior areas received their initial coats, and numerous coats were applied to the saloon interior to establish a robust protective barrier.

In the engineering department:

It wasn't as busy, but many ball valves had corroded and deteriorated, necessitating replacements, especially in the fuel manifold, tanks, and bilge/sewage pumping systems. The main engine heat exchangers were removed and serviced with a fresh coat of paint.

As Peats Bite inched closer to their DA approval for the restaurant's reconstruction, our time at Sunny Corner neared its end. The accomplishments had been nothing short of extraordinary, and the working environment had been unparalleled. We also needed to vacate the cottage we'd called home for the past year.

Word circulated along the river, seeking a new location, and fortunately, we were introduced to 33 Milsons Passage. We secured a slipping at Dolphin Marina, embarking on the next phase of this remarkable journey.

Destruction for Construction

The can of worms had more worms than expected...

With all restoration projects, it's important to get to the good substrate and rebuild from there. Out with the old in with the new.

Our new alliance with Peats Bite allowed us to really advance in the deconstruction and refinishing process of the Margordel. We acknowledged that there was more to do than originally anticipated.

Chasing the rot into unexposed areas and behind the facing timbers. With the team all living on-site, we had the perfect opportunity to move forward. Geoff arranged a large marquee for a workshop also power and water. We were able to take all the parts that we could remove, repair, and resurface within the workshop space. Significant hours were engaged through this process.

The following items were removed during this process:

-

The bulwarks – these had rot in the lower sections where water was trapped. A new design was required to allow better water runoff.

-

The galley – The old fridges were subject to a lot of deterioration. They were the old-style eutectic fridges/freezers, only accessed from the top. They had a separate compressor system in the engine room which had suffered neglect and would have to replace the entire system. It was neither cost-effective nor space-effective to reinstate them into service. The galley sink and cupboards were removed for painting and to access the tanks and inner hull.

-

The aft cabin cabinetry – had a rotten top surface, the facing timbers were still intact and will be reinstalled once the cabin side has been locked up.

-

Head and Shower – Cabinets were removed to access the hull for painting.

-

The Saloon – the inbuilt seating was removed to access the hull and beams. Ready to reinstall upon lockup.

-

The Skylights – to be lovingly restored with some minor repairs, fine hand sanding and sealed with fresh glass, and coated with varnish.

-

The Cabin Doors – These had to be significantly rebuilt, sanded, and re-routed with varnish.

-

Forward window – This very classic feature needed to be resealed and minor repairs to the timberwork. Coated with varnish.

-

Ceiling Slats – Thankfully most of these pieces were in good condition, however, they were stripped, meticulously sanded, and coated with varnish.

-

Hull covering Slats – This jigsaw puzzle of mahogany pieces stretched most of the length of the boat covering the inner hull and ribs. They were restored with varnish.

-

Lazarette shelving – The shelving in the lazarette was taken out to allow a full repaint of the space. They had some minor repairs and are due to be reinstalled once the hatch is finished. Each piece is now painted and ready for installation.

-

Brass Lights – These beautiful period lights are solid brass and will be an extraordinary feature of the finished product. Unfortunately, some of the glass has been damaged and we are searching for a replacement.

-

Daurade Boxes – These are another extraordinary feature of any classic yacht and the mahogany-constructed boxes were quite weathered, in some cases, they needed to be completely restored with fresh epoxy joins. These have been resurfaced to a rustic level which still shows the aged cracks in the timber and coated with varnish.

-

Engine Breathers – This classic feature mounted on the cabin side has half flue in and out. They are awaiting pride of place upon final cabin side varnishing cycles.

All these components have endured countless hours of nourishment and attention, carefully brought back to glory from the neglect and weather they were subject to. We have endeavored to keep them as original as possible and value repair rather than replacement.

In our in-depth investigation, it became apparent that we needed to rebuild a substantial portion of the cabin side from front to back. This was not what we had originally wished however, with consolation by the shipwrights we would be building in areas that would be hard to access later down the track. This means repairing sheets of ply and beams that have been damaged and were advised to be replaced in full instead.

We had made the conscious decision at the start to do things thoroughly and to a professional standard, so we went ahead. The team ‘carefully’ removed the rotten sides, and props were erected to keep the shape whilst the beams and posts were spliced with new timber.

The enormity of the project was really hitting home at this stage. We had a team of 3 shipwrights and 2 labourers working long days to deconstruct and reconstruct.

The areas fully rebuilt were:

-

Forward Trunk Cabin – The forward locker and the substructure in the forward rise. A mixture of Mahogany and Oregon beams and supports were replaced with the surrounding epoxy-soaked ply structure around it.

-

Starboard Head (Toilet) – This rot continued down the sheets of plywood that surrounded the starboard toilet. This room is in between the galley and the forward cabin. It was laminated in Laminex to help with internal water ingress, but the water ingress was external which caused the ply to rot out halfway on the forward side and the entire aft side of the plywood structure. New epoxy-soaked plywood was installed creating a mid-bulkhead.

-

Main Trunk Cabin – The forward trunk cabin walls and the outer laminated mahogany cladding had let go and let water eat away at the structural integrity of the sides. These had to be removed and the damages had to be well assessed. It was found that the Oregon structural longitudinal beams were in sound condition and had been resurfaced and epoxy-treated in readiness to accept the new ply and mahogany cladding.

-

Saloon and Master Cabin - The same fate was for the cabin side in the saloon and the aft master cabin. Structural supports were wedged into place. The removal of the timber was in layers, firstly with the saloon seating removal, and in the aft cabin each facing slat and bordering surrounds were carefully removed.

-

Under-deck structural Beam – The under-deck beams under the fuel tanks were previously repaired in housing LVL timbers which disintegrated. We painstakingly designed a laminated Oregon repair which needed to notch into the longitudinal hull beams and spliced in the middle.

-

Lower Longitudinal Beam – The starboard saloon cabin side was full of rot from both fungus and fresh water. The lower longitudinal beam had to be replaced from the door to the master cabin. It was a thick beam with a curve in three planes, which made installation difficult. We overcame this by cutting the beam in two pieces and laminating them together with the required shape otherwise not attainable in one piece. This was then bolted to the under-deck beams.

-

Underdeck Plywood – the side decks had been found to be water-damaged in some areas. We did not wish to remove the teak deck above, so we had to grind away the ply from underneath and perfectly shape new pieces of ply to slot in under the teak deck and over the outboard longitudinal beam. This was a challenging jigsaw puzzle.

-

The saloon sole board – Was okay but not to the required standard, so it was replaced by a new sheet of epoxy-soaked ply.

-

Master Cabin Deck-head Plywood – The Master cabin deck ply had to be replaced in the forward section of the rear deck which had a camber curve to allow for water runoff.

-

Master Cabin Deck Beams – Several of these had significant rot in the starboard section of the beams. These Maple beams needed new pieces spliced in with the same deck camber curve and secured through the deck with screws and glue.

-

Lazarette Deckhead Plywood – Further to the deckhead plywood on the side deck the aft deck was no different. Carefully crafted pieces of plywood were glued to the underside of the teak after the team had meticulously ground out the old rotten substructure.

-

Lazarette Structural Beams and Posts – This rot also affected some of the structural beams in the aft lazarette. These were replaced in full around the hatch and scarfed in the saveable areas along the bulkhead wall.

-

Sponsons – The surrounding sponson band was heavily deteriorated by rot in a few places. During this period, we replaced the majority of the starboard side. This was replaced by Spotted Gum which is less prone to rot.

As you can imagine our little isolated workspace was a hive of activity. The labourers lived with us in the cottage and the Shipwrights were collected by boat each day. A special thanks to our team for this effort. We never compromised for a quality thorough result, always thinking about the long term and making sure that we didn’t create problems later down the track.

Whilst all this productivity was going on we had two flood events. The first flood, in March 2022, was like Armageddon. We were very lucky to be where we were, as just one mile up the river had a flood reading of seven meters. Sunny Corner is in the Hawkesbury tidal basin. Berowra Waters is the shock-absorbing waterway where the river meets the tide. The water level rose only 15cm over our seawall and stayed at high tide levels for a week.

The damage to us and the boat came from the debris streaming down the river. Everything from caravans to gas bottles, to trees and livestock. This called the project off as it was too dangerous to leave the house at times, and we would never consider navigating at night. We were constantly clearing the Margordel of trees and debris piling up against her. The token Tarpaulins were no match to the volume of rain we and the rest of Sydney encountered.

Our relationship with Peats Bite was of mutual benefit. In the aftermath of the fire, the owners needed reassurance that trusted people were on site and helped with the day-to-day running of systems of the off-grid venue. They had been very busy planning for the redevelopment. We were very grateful to be utilizing the space, but we knew that it was only temporary until they had their DA in process, and they could prepare the site for development.

Mid-May 2023 we had to vacate our marquee workshop and set up our workspace under the cottage at number 3 Sunny Corner. This gave Geoff the time he required, and we would still be welcome to have the Margordel alongside the wharf.